IBC types – which is the better option for you?

The food oil industry has long relied on traditional plastic IBC containers as the standard for storage and transport. At Nordic Hemp, we are introducing a more sustainable alternative — a durable cardboard IBC solution with a replaceable inner liner. This innovative packaging significantly reduces plastic use and lowers environmental impact, while maintaining the strength, safety, and efficiency required for handling oil products.

Cardboard IBC 1000L with replaceable liner

The cardboard IBC also known as SpaceKraft® is an intermediate bulk container (IBC) used to transport non-hazardous liquids worldwide. Manufactured under patented technology, SpaceKraft® is continuous sheet of paper shaping into 8 plies of A-flute corrugated. The result is a seamless container with extraordinary strength; from 20 to 37 tons of top-to-bottom compression strength.

When it comes to transporting and storing nonhazardous liquids, SpaceKraft containers provide a new perspective. Strong, easy-to-use, space efficient and disposable, SpaceKraft products make shipping and storing liquids simple and economical.

Why use SpaceKraft IBC-s ?

1. Significantly More Sustainable

SpaceKraft cardboard IBCs are made primarily from recycled corrugated board, reducing reliance on fossil-based plastics. The outer container is recyclable, and only the inner liner requires disposal after use — dramatically lowering overall plastic waste.

2. Reduced CO₂ Footprint

Compared to traditional plastic or metal IBCs, cardboard IBCs have a substantially lower carbon footprint in production and disposal, supporting ESG and sustainability goals.

3. Lightweight but Strong

Despite being made from multilayer corrugated board, SpaceKraft IBCs are engineered for high load capacity and stability, suitable for transporting liquids safely.

4. Food Industry Approved

Suitable for a wide range of applications including oils, juices, dairy, syrups, emulsions, lubricants, and other liquid products.

5. No Cleaning Required

Unlike rigid plastic IBCs, cardboard IBCs eliminate washing and cleaning processes. This reduces water use, labor, contamination risks, and turnaround time.

6. Strong Sustainability Branding Value

Switching to cardboard IBCs visibly demonstrates commitment to environmental responsibility — increasingly important for customers, retailers, and regulators.

Gallery:

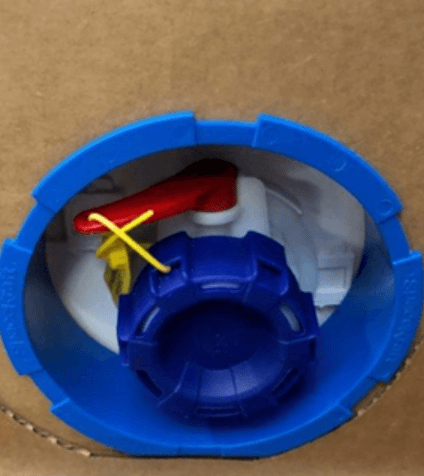

1000L Plastic IBC Solutions for Food Oil

1000L IBCs (Intermediate Bulk Containers) are widely used in the food oil industry for the safe storage and transportation of large volumes of edible oils such as hemp seed oil, rapeseed, sunflower, olive, and other vegetable oils. Their cubic shape maximizes pallet and warehouse space efficiency, while integrated discharge valves allow for controlled and hygienic emptying during production. Whether used for domestic distribution or export, 1000L IBCs provide a practical, and reliable bulk packaging solution for food oil manufacturers and processors.

Nordic Hemp also offers the traditional 1000L plastic IBC option for customers who require it or whose processes are currently built around rigid plastic containers. However, as part of our commitment to reducing environmental impact, this option comes with additional cost. We are actively working towards more sustainable packaging solutions and therefore prioritize our cardboard IBC system, which significantly reduces plastic usage and overall carbon footprint. While plastic IBCs remain available, our long-term focus is on helping partners transition to more responsible and future-oriented packaging alternatives.